+++ From now on, the universal blade jig for third-party machines is sold exclusively through www.messermaterial.at +++

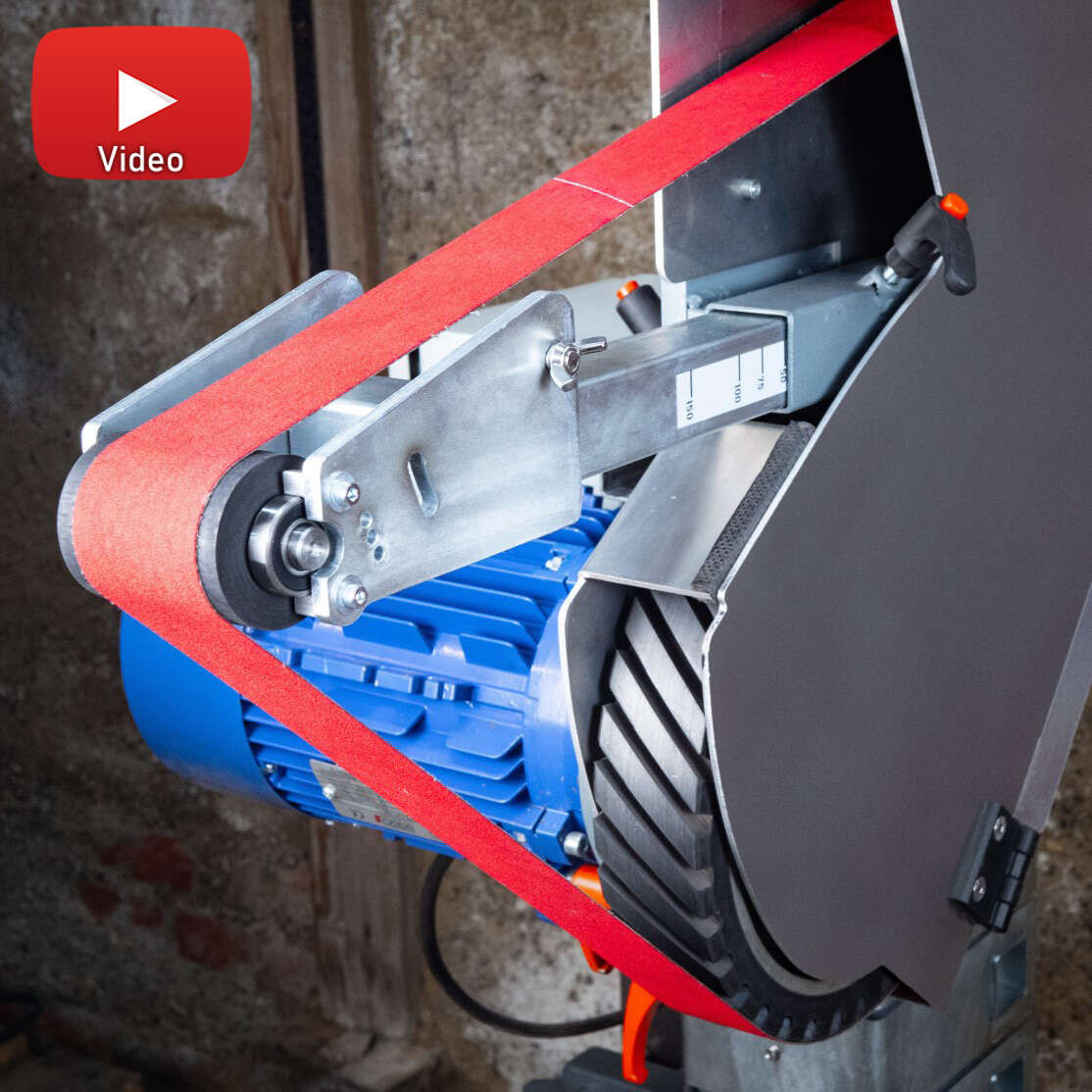

Knifemaking means dealing with complex shapes and geometries that require a high finish quality. Each workpiece and process is unique. Using a good belt grinder is a great start, but reaching and grinding all surfaces, edges and transitions on a workpiece efficiently is also a matter of having a set of great attachments.

For this reason, I developed a rich set of attachments to the belt grinder BS-1, which is continuously expanded.

Although these attachments were designed to be used with the BS-1, some of them (like the very popular universal blade jig, the radius and ricasso platens and the surface grinding attachment) can also be fit to grinders of other brands or makeshift machines. With my abilities in designing an manufacturing, adopting attachments to your grinder or finding the perfect solution to your individual problem is fast and affordable!

You want to find out more? Get to know all the attachments in the interactive pictures below!

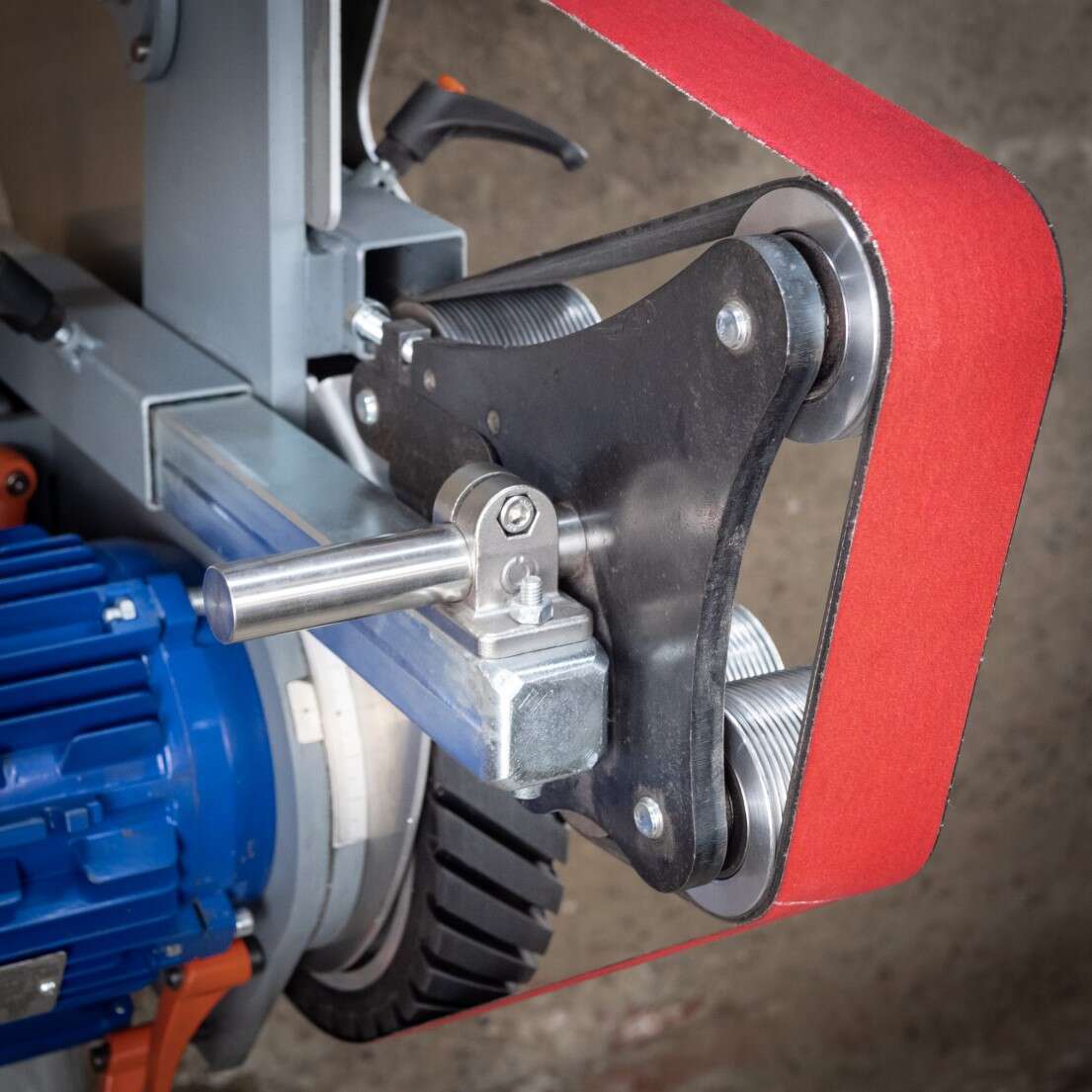

Radius grinder

The radius grinder is one of the most common attachments. Whenever tight concave features are to be ground, it's the tool of choice. The radius grinder can be combined in various setups with other attachments.

Click the marked regions in the picture to learn more!

Position Indicator

The tool arm has a position indicator that shows where to clamp the attachment, depending on the used wheel diameter.

Radius wheels

The radius grinder comes with three wheels of 19, 32 and 50mm diameter. The wheels are a bit wider than the belt to make using the ricasso and integral attachment easier.

Wheels in 75 and 100mm diameter can be purchased as add-ons. These wheels are exactly as wide as the grinding belt, to make it easy to grind fullers etc.

The diameter limit of the radius grinder is 150mm.

Slack belt

On the side, the radius grinder offers a long slack belt that is ideal for shaping handles or other freeform shapes.

Height adjustment

The BS-1's angle adjustment can be used to set the height of the radius grinder to the desired ergonomic working position. This also allows for a precise setup in combination with the grinding table or the surface grinding attachment.

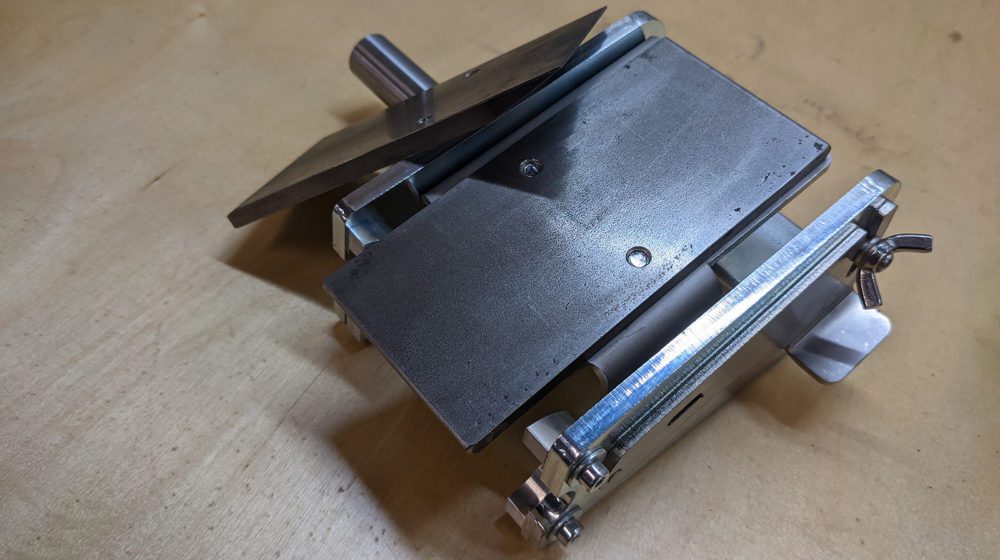

Ricasso and integral attachment

Probably the biggest timesaver in the range of attachments to the BS-1! Grind longitudinal finishes on blades, even if they have features that traditionally call for hand sanding. Finish plunge lines and integral transitions with ease, up to a grain of P600 or finer.

Click the marked regions in the picture to learn more!

Fine adjustment

The fine adjustment helps to get the alignment of the grinding plate perfectly to ensure smooth transitions.

Mount

The attachment is mounted inside the radius grinder and can be added or removed quickly.

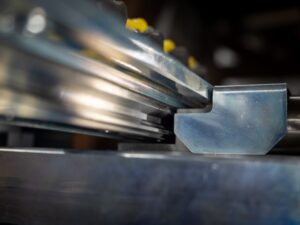

Grinding plates

Depending on the result to be achieved, different grinding plates are used.

The plate for grinding ricassos / plunge lines can be rotated four ways for different transition radii between 1-3 mm.

The plate for grinding integral knives can be combines with the radius wheels 19, 32 and 50mm.

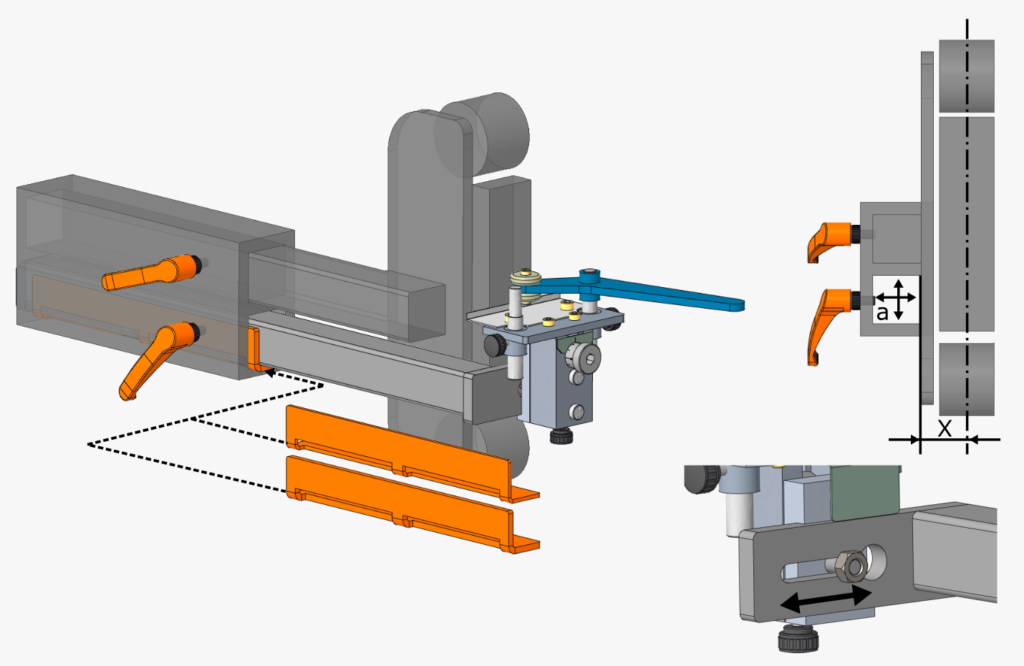

Universal blade jig

Grinding blades freehand is challenging for beginners and time consuming and prone to mistakes, even for professionals. This universal blade jig is the result of a collaboration with professional knifemakers Benjamin Kamon and Tobias Hangler. Even for class participants or novices, it makes it easier to master even more complex grinds.

The blade jig can be used for plain grinds, hollow grinds or S-grinds in the corresponding areas of the BS-1. It can also be adapted to use on 3rd party machines. More information on compatibility of the blade jig with other machines.

Purchase the universal blade jig exclusively from www.messermaterial.at!

Click the marked regions in the picture to learn more!

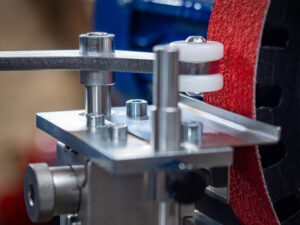

Pressure wheel

Pressure is applied to the blade with a lever that connects to the pressure wheel. The plastic wheels do not leave marks on the blades and have little friction. The hinge posts of the lever are adjustable in height, to accommodate for the individual blade shape.

Depending on personal preference or when grinding very fragile geometries, the hinge bolts and the lever can be removed entirely, so that the blade can be guided by hand.

Blade retainer

The blade retainer determines the grinding angle by holding the blades spine at a certain distance to the grinding belt. The retainers are made from 1mm stainless sheets and can be ground to shape according to individual needs. The attachment comes with 3 pcs of retainers.

Fine adjustment

The grinding angle is determined by the distance between blade retainer and grinding belt. The adjustment screw allows to make precise changes in the angle on-the-fly.

Use on contact wheel

The attachment can also be used with the contact wheel, to create hollow or S-grinds. A tool arm for the contact wheel is included in the order for BS-1 users.

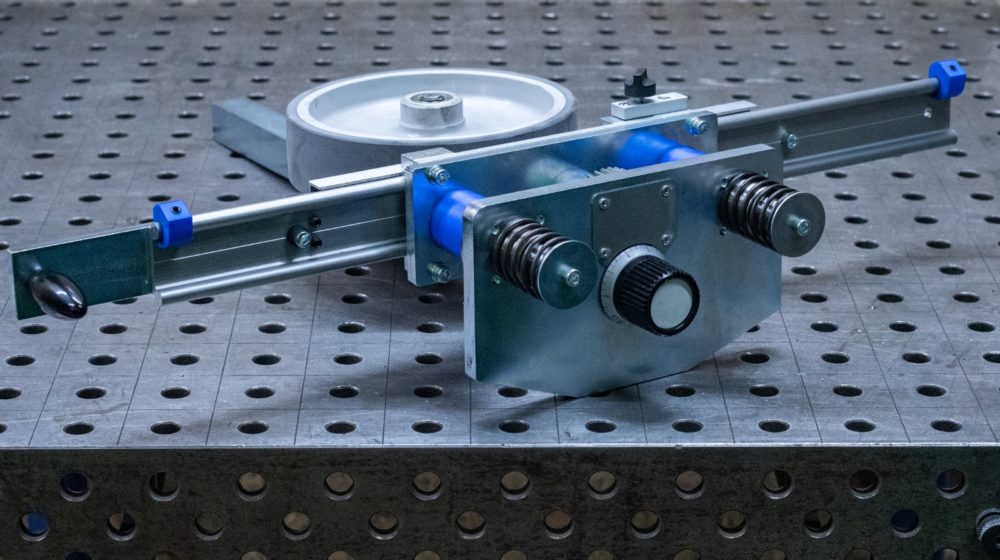

Surface grinding attachment

Turn your belt grinder into a surface grinder! Grind straight, parallel surfaces for finishing blades or stacking damascus steel. Combine the attachment with the radius grinder to grind guided fullers or bevels. Taper blades or handles with the taper function. The surface grinding attachment has seen a complete redesign and now offers even more precision, easier handling and even better results!

Click the marked regions in the picture to learn more!

Adjustable stops

Adjustable stops can be set to limit the travel. They are damped by rubber rings.

Gauge adjustment

The gauge adjustment works with a fine thread spindle and is very sensitive. The turn knob is equipped with a scale with a resolution of 0.01mm.

The distance from the contact wheel goes from 0-60mm.

Slider

The grinding slider uses a precision linear bearing and is covered and sealed against dust. The standard travel way is 300mm, but custom travels, for example for swordsmiths, are possible!

Magnetic chuck

The magnetic chuck uses switchable ND-magnets to securely clamp and easily remove the workpiece. The holding force per magnet unit is 40kg (assuming full coverage of the magnet)

Taper function

The taper function has been completely redesigned and now allows for taper angles up to 2° or 3.5mm per 100mm. An adjustment jig is supplied to make setup of a taper angle very easy.

Contour grinding table

Grind exact 90° contours with the contour grinding table. It can be combined with the radius grinder, the contact wheel and the flat platen. The tilt mechanism of the BS-1 allows for perfect ergonomics and a clear view of the results.

Click the marked regions in the picture to learn more!

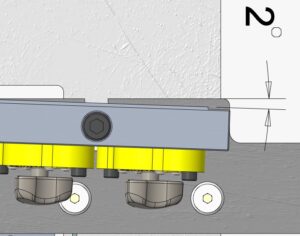

Lateral adjustment

The table can be shifted across the whole width of the belt to prevent hot-spots in which the belt wears out fast.

2 in 1

The table has cutouts to work with the radius grinder and the contact wheel.

Serration grinding attachment

Grinding serrations used to involve either a lot of manual work or buying an extremely expensive abrasive wheel for each serration size. The serration grinding attachment offers a very economic way to create, sharpen and hone serrations.

Click the marked regions in the picture to learn more!

Jig

The serration jigs are designed so that a flexible grinding belt wraps around them and transfers the shape of the jig to the blade ground.

Two jigs with 14 and 20mm diameter are provided and can be switched out without taking off the belt. These diameters fit the most common serration sizes. Individual diameters can be supplied or quickly made.

Table for contact wheel

Use the full power of the BS-1 with the table for the contact wheel! With a solid work rest, it is easier and safer to work with high pressure and rough grinds on the contact wheel. The table attaches to the lower mounting point of the BS-1 and has an angle adjustment to help create hollow grinds using a jig.

Click the marked regions in the picture to learn more!

Angle adjustment

The table can be adjusted so that the distance from the table surface to the center of the wheel changes. This way, one can find the perfect setup to create a hollow grind.

Table size

The table is made from steel and measures 120x300x8mm.

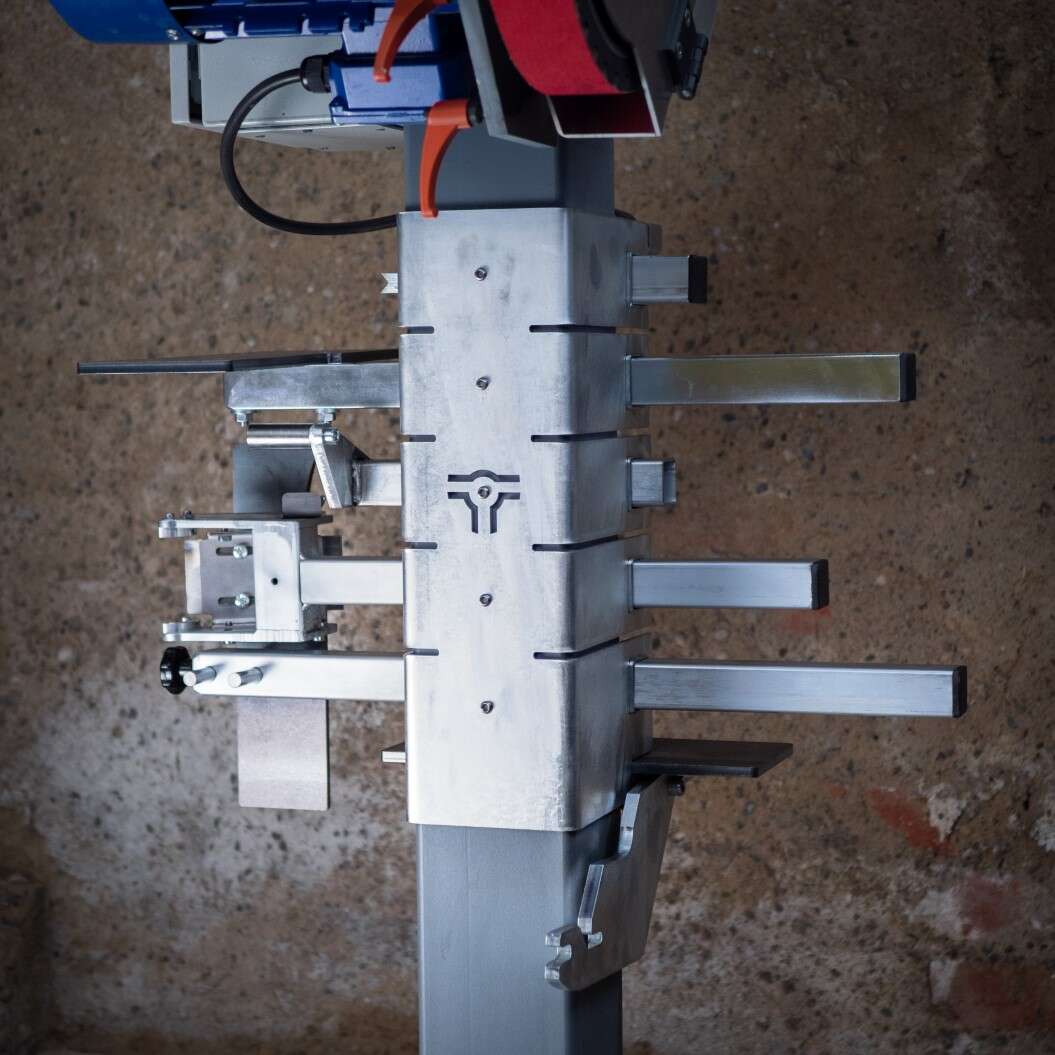

Tool holder

Organize your attachments using the tool holder. It easily attaches to the stand of the BS-1 and offers space for 5 attachments with tool arms, the table for the contact wheel and small parts like radius wheels.

The tool holder is not compatible with the table-mount version of the BS-1.

Click the marked regions in the picture to learn more!

Shelf for small parts

Easy setup

The setup on the machine is quick and doesn't require drilling holes.

Cooling system

No more overheated blades! The cooling system ensures a stable process and increases the works speed at the same time. The system uses pressurized air to create a mist using water sucked from a tank or the water tap. The mist can be regulated precisely so that the cooling effect is similar to flood cooling - just without the mess and with little water consumption.

The system includes a water hose with filter. The supply for pressurized air has to be provided by the customer. Air consumption: 120 L/min at 4 bar.

blank

Water basin

Water and dust - both are common yet unpopular elements around a grinder. The water basin helps to keep the surroundings of the BS-1 clean. A generously sized basin catches water, can be used to cool workpieces and acts as a reservoir for the cooling system.

The optional suction hood that goes on top of it creates a pull from within the basin. The deflection of the airflow around the water surface causes a separation of dust and sparks.

The suction hood is only compatible with floor-mount machines.

Click the marked regions in the picture to learn more!

Stainless basin

The stainless steel basin measures 325 x 265 x 200mm and is inserted from the front.

Mount

The basin mounts either to the Stand (floor mount grinders) or to the workbench (table mount). In both cases, the bracket that holds the basin can easily be removed out of the way if no basin is being used.

Suction hood

The suction hood comes with a custom flange for hoses up to 100mm. Please let me know your hose diameter upon ordering!

The hood can quickly be removed to use the basin without it.

3rd party attachments

You'd like to switch to a BS-1 but want to take your old attachments with you? Or you want to use a rotary platen like in the picture? The 3rd part adaptor allows to mount attachments that use the widespread 20mm shaft system for clamping. Please contact me to check if your attachment is compatible!

blank

You are using a different belt grinder, but you are interested in the attachments listed here? The most popular attachments are also available for other machines!

Universal blade jig

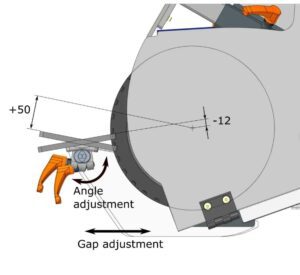

The universal blade jig is very popular and already in use on many different machines. From the beginning, it was made to fit various belt grinders for knifemakers without design changes. The following requirements have to be met in order to mount the jig without modifications:

- The grinder takes attachments with a square tool arm coming from the left or right of the grinding belt. There is a free clamp available to attach the jig to.

- The size a of the tool arms is either 35mm, 40mm or 1.5" (38.1mm) square. For the 1.5” variant, the 35mm arm is combined with a shim (orange in picture)

- The distance x between the tool arm clamp and the center of the grinding belt is anywhere between 35mm and 70mm. The user can adjust the jig to the machine's measurement by an oblong hole.

If all these requirements are met, you can use the universal blade jig on your grinder!

Other attachments

Also the other attachments are available for third party machines. This usually requires only the tool arm to be changed. Just send me an email, ideally with a few photos of your machine. I will then ask for a handful of measurements and can create a custom tool holder that matches your machine perfectly and comes at a fair price. A few examples below:

Prices as of February 2024. Prices are subject to change.