+++ Now available! Inquire today! +++

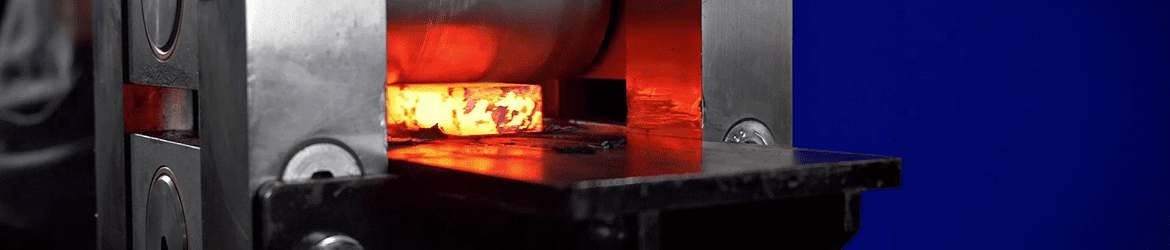

High thickness reduction is a common and yet one of the most time consuming steps in traditional forging. Especially the forging of damascus steel often requires the blacksmith to reduce material from 60mm to as low as 3mm thickness. The best machine to speed up this process is a rolling mill as it offers a quick and precise way of reshaping hot metals. Being free of noise and vibrations, a rolling mill is suitable for every shop and gets the job done more efficiently than a power hammer or press.

Unfortunately, besides some occasionally offered second-hand goldsmith machines, there is no market for rolling mills that are suitable in size and price for most blacksmiths.

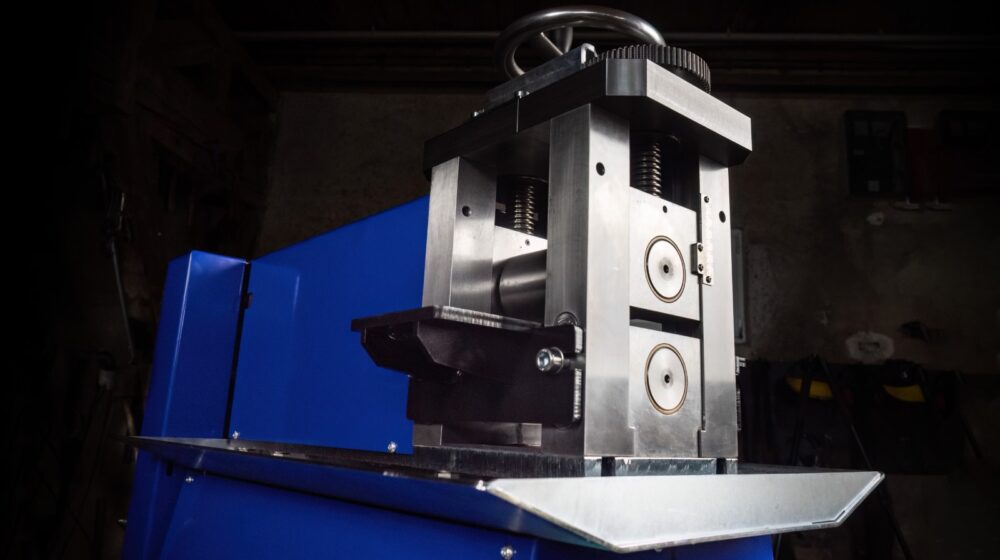

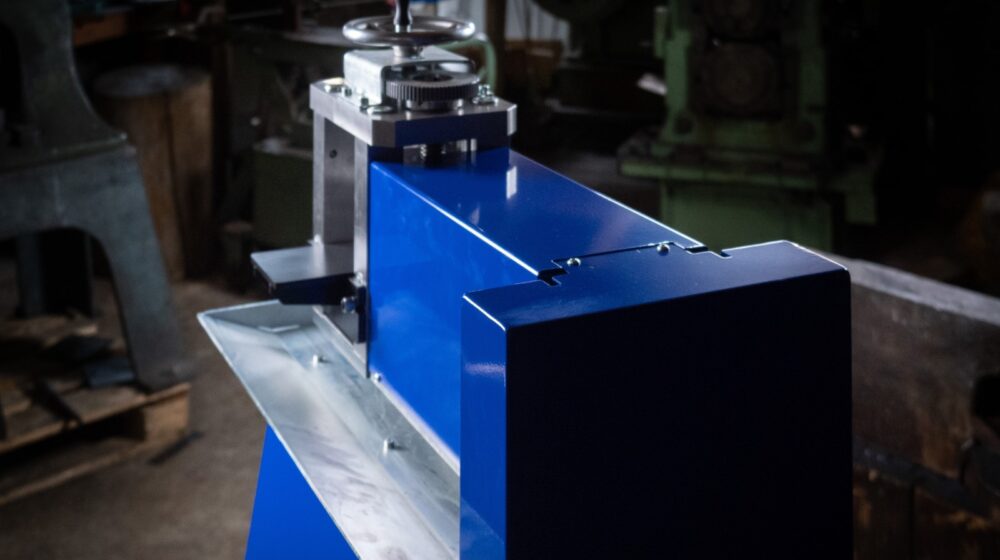

Until now, that is: The Tobin RM-1 ist the first machine to offer a robust and affordable package. Designed and built in Austria, the machines have a very high build standard. Increase your productivity, be it with making damascus steel, pre-shaping steels from large stock sizes or for making tools and artwork of all kinds.

Technical specifications:

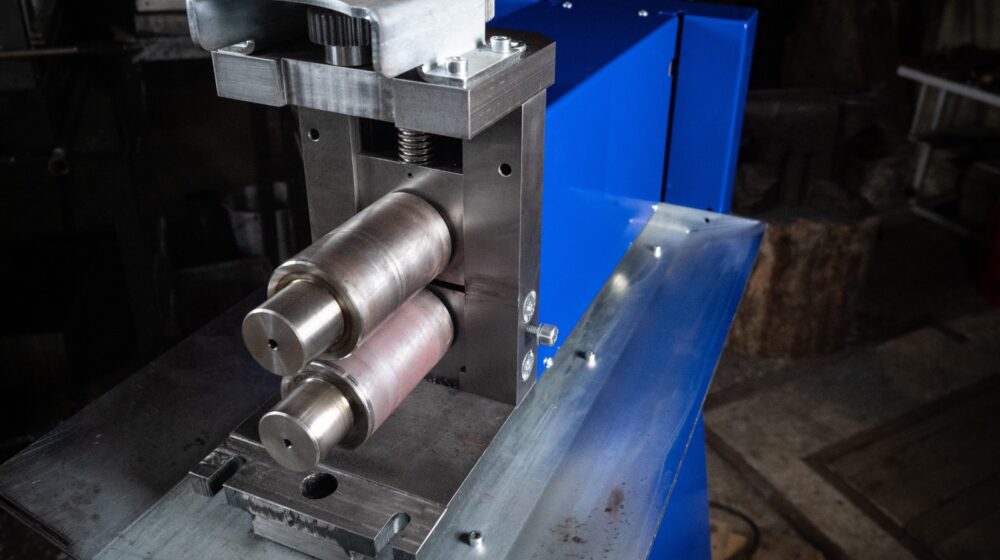

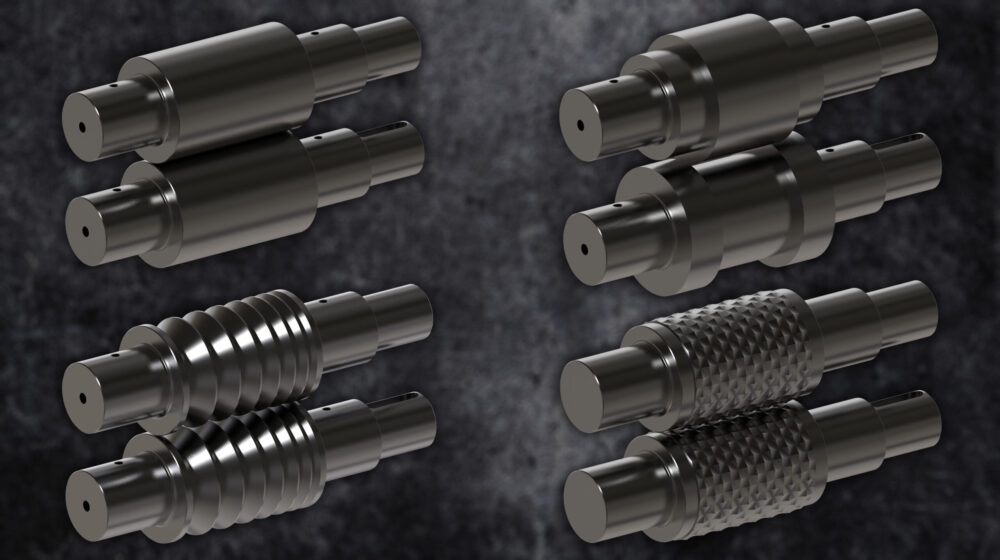

- Rollers: 42CrMo4, quenched, tempered and nitrided, diameter 70 mm

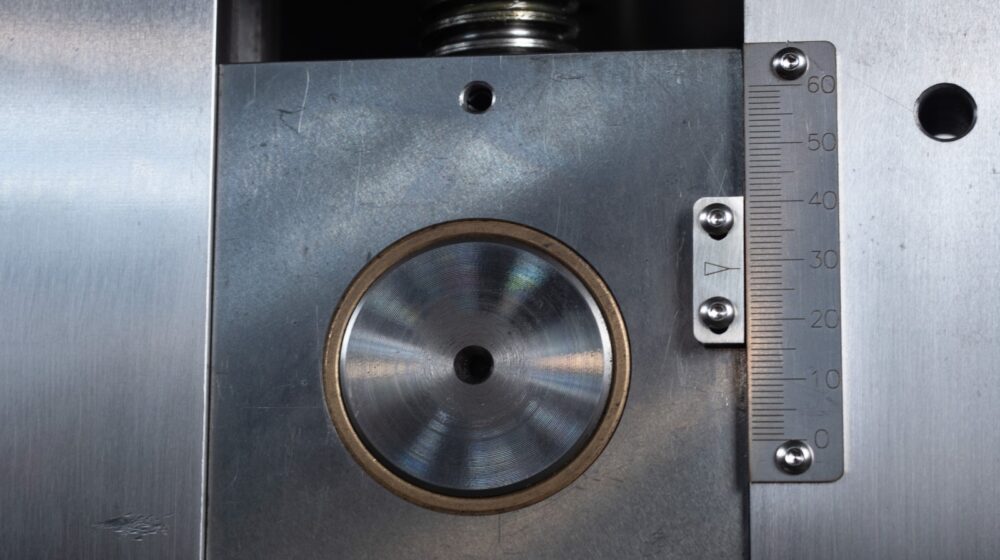

- Workpiece thickness: 0-60 mm

- Workpiece width: max. 110 mm

- Drive system: Electric gear motor 3 kW with brake, secondary transmission with chain

- Thickness reduction depending on temperature, material and workpiece shape up to 4 mm.

- Operation mode 1: continuous mode, roll out workpieces in constant direction with a helper to return the piece

- Operation mode 2: reversing mode, roll out workpieces alone and easily switch the direction to return the piece to the original side of the machine.

- The design allows the rolls to be switched out in as little as 10 minutes. Rolls for profiles or damascus patterns will be offered subsequently.

- Thickness ruler for precise manufacturing

- Adjustable safety clutch prevents overload

- CE certified design with safety pedal switch

- Bearing system based on bronze bearings, lubrication points easily accessible

- Easy to clean design

- Only high-quality components

- Structural parts are coated or painted

- Weight and size: 260 kg, 1600x850x650 mm